designers and fabricators of stained glass windows for synagogues

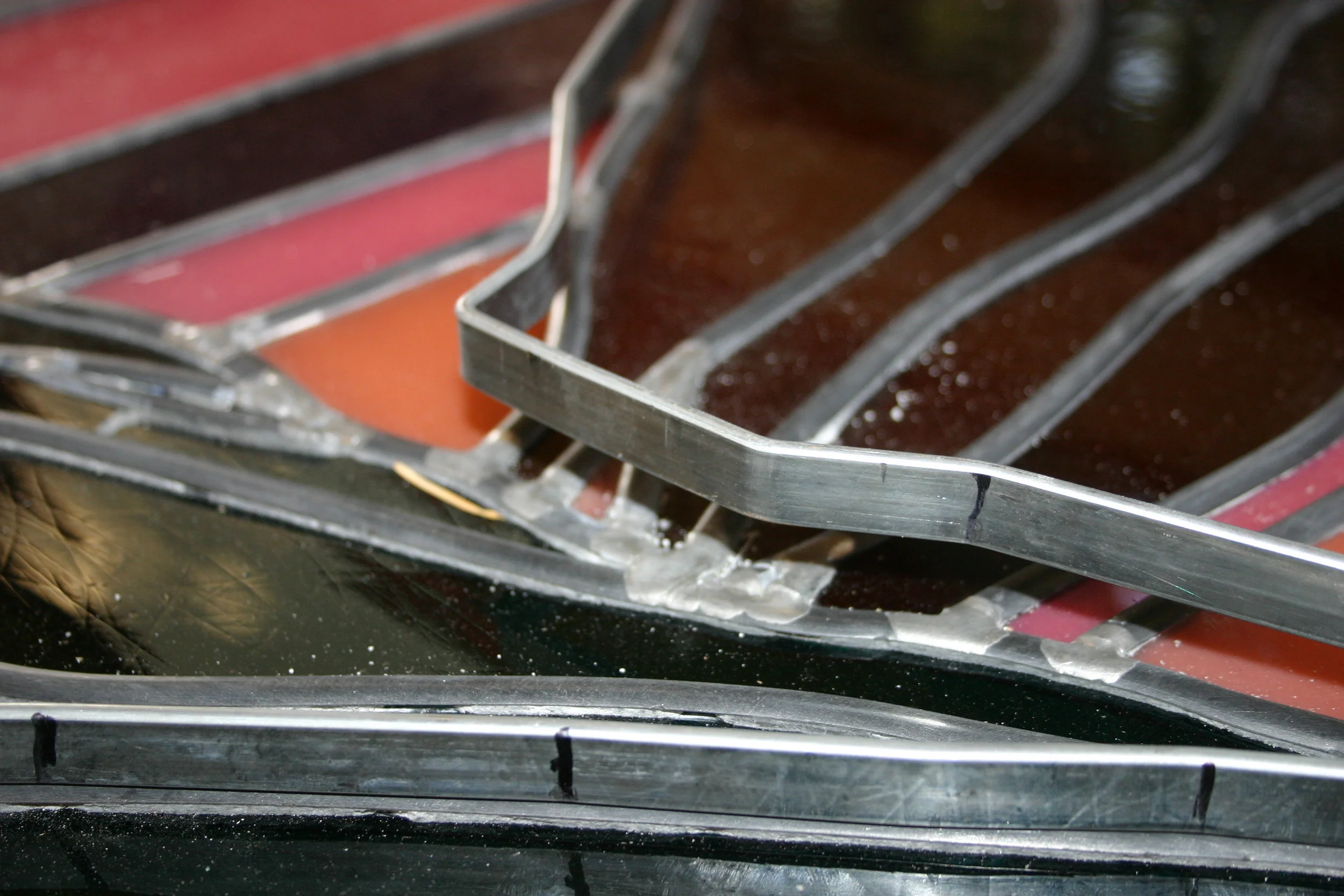

Each panel needs reinforcement by rigid members in order to stabilize it in the vertical position. Moreover, in order to resist gravity for the minimum of 50 or so years of a panel's intended life, this reinforcement has to be extremely durable. For this reason, we employ solder-coated steel bars welded to the surface of the lead and bent to conform to existing lines in the design.

Bending and welding the steel bars is David's job. Depending upon the intricacy of the design, bending the bars needs to be accomplished by an exacting and painstaking process of successive approximations by hand and eye.

After all the steel bars are welded to the lead, the window is masked off completely so that the bars may be spray-painted black to further minimize their appearance.

Each panel needs reinforcement by rigid members in order to stabilize it in the vertical position. Moreover, in order to resist gravity for the minimum of 50 or so years of a panel's intended life, this reinforcement has to be extremely durable. For this reason, we employ solder-coated steel bars welded to the surface of the lead and bent to conform to existing lines in the design.

Bending and welding the steel bars is David's job. Depending upon the intricacy of the design, bending the bars needs to be accomplished by an exacting and painstaking process of successive approximations by hand and eye.

After all the steel bars are welded to the lead, the window is masked off completely so that the bars may be spray-painted black to further minimize their appearance.

Fitting the bent steel bar to the lines of the design.

Steel bar laid on the panel shows the bending points marked with a Sharpie marker.

The steel bars are masked off with tape in preparation for painting.

David fits a re-bar to a panel in the assembly room at the Sherwood Ranch Studio.

Re-bars laid on a panel prior to soldering.

The re-bars are masked off for painting.

Reinforcing Stained Glass Windows with Steel Bars